A dynamic checkweigher is an industrial system that weighs products in motion on a conveyor, ensuring precise quality control during high-speed production. It employs synchronized belts for smooth product transfer, load cells for accurate weight measurement, and signal processing to refine data. Multiple weight readings are captured and averaged as items cross the weigh belt, minimizing errors through vibration control. Exploring further unveils deeper insights into its mechanisms and diverse industrial applications.

Key Takeaways

- A dynamic checkweigher is an industrial system that weighs products in motion on a conveyor for quality control.

- It ensures 100% inspection by identifying out-of-tolerance items for rejection at high speeds.

- Conveyor belts synchronize product spacing, while load cells measure weight with precision.

- Signal processing and dynamic sampling refine data for accurate weight calculations during transit.

- Vibration control and rigidity minimize interference, ensuring reliable operation in production lines.

Understanding the Basics of a Dynamic Checkweigher

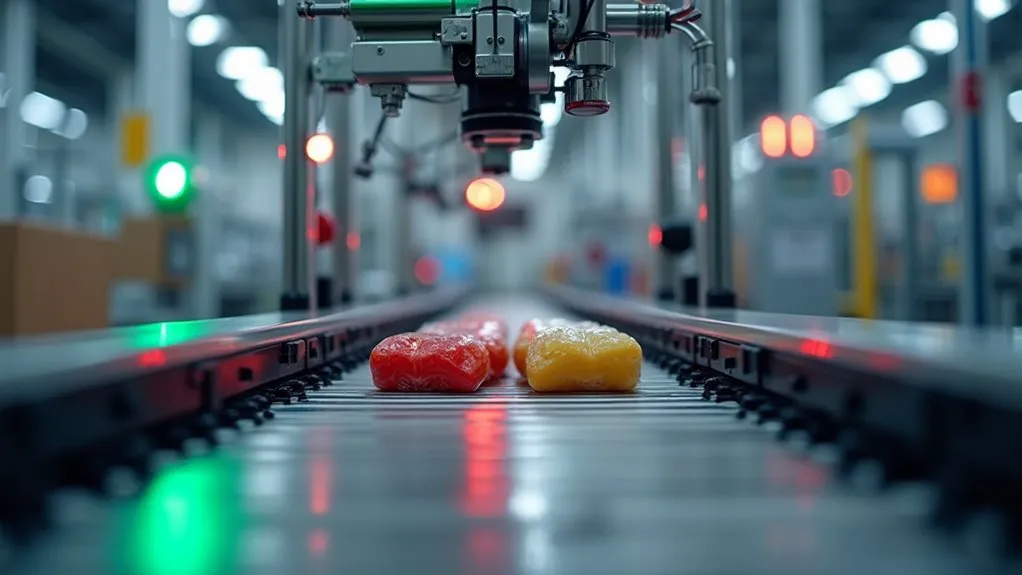

A dynamic checkweigher is an advanced industrial system designed to weigh products in motion on a conveyor, distinguishing itself from static scales that require products to stop for measurement. This technology ensures 100% inspection of packaged goods, identifying out-of-tolerance items for rejection, thus safeguarding quality control and compliance with weight regulations. Its high-speed, continuous operation enhances production throughput while minimizing product giveaway and underfilling through precise weight feedback. Additionally, it can handle up to 500 items per minute depending on product size and required accuracy, ensuring efficiency in fast-paced environments.

Integral Safety Features protect both operators and equipment, with emergency stop functions and protective barriers preventing accidents during high-speed sorting. Meanwhile, Cost Factors play a critical role in adoption, as initial investment and maintenance expenses must be weighed against long-term savings from reduced waste and regulatory fines. Designed for seamless integration into existing lines, dynamic checkweighers serve diverse industries like food, pharmaceuticals, and logistics, ensuring accuracy and efficiency in weight verification processes.

Key Mechanisms Behind Its Operation

Building on the foundational understanding of dynamic checkweighers, attention now shifts to the intricate mechanisms that drive their operation. These systems rely on precise engineering to ensure accurate weight measurements in motion. Central to their function is the integration of advanced technologies like Dynamic Sampling, which captures multiple weight readings as products traverse the weigh belt, and Vibration Control, which minimizes noise through stable designs and digital filtering.

Key mechanisms include:

- Conveyor Synchronization: Multiple belts coordinate to maintain product spacing and smooth transfer.

- Load Cell Precision: Strain-gauge or EMFR technologies measure vertical force with high accuracy.

- Signal Processing: Filters and algorithms refine raw data for reliable weight calculation.

- Dynamic Sampling: Ensures consistent readings by averaging weight data over time.

- Vibration Control: Employs rigidity and active compensation to reduce external interference.

These components collectively enable the checkweigher to perform with exceptional accuracy under demanding conditions.

Primary Uses and Advantages in Industry

Dynamic checkweighers serve as critical tools across various industrial sectors, delivering precise weight verification and process optimization. They ensure Regulatory Compliance by adhering to stringent weights and measures laws, such as EU Directive 76/211/EEC, and support industries like food and pharmaceuticals in meeting legal metrology standards, thus avoiding penalties. Simultaneously, they enable Cost Reduction by minimizing product giveaway, reducing waste, and automating weight checks to lower labor expenses.

Their versatility enhances production efficiency, quality control, and brand protection. The table below illustrates key industrial applications:

| Industry | Primary Benefit |

|---|---|

| Food & Beverage | Ensures weight accuracy, reduces waste |

| Pharmaceuticals | Meets strict compliance, quality control |

| Cosmetics | Guarantees consistency, customer trust |

| Chemicals | Prevents overfilling, optimizes material |

| Logistics | Streamlines throughput, verifies loads |

Through high-speed operation and data integration, dynamic checkweighers uphold standards while driving operational efficiency across diverse sectors.

Tiếng Việt

Tiếng Việt 日本語

日本語 中文 (中国)

中文 (中国) 한국어

한국어