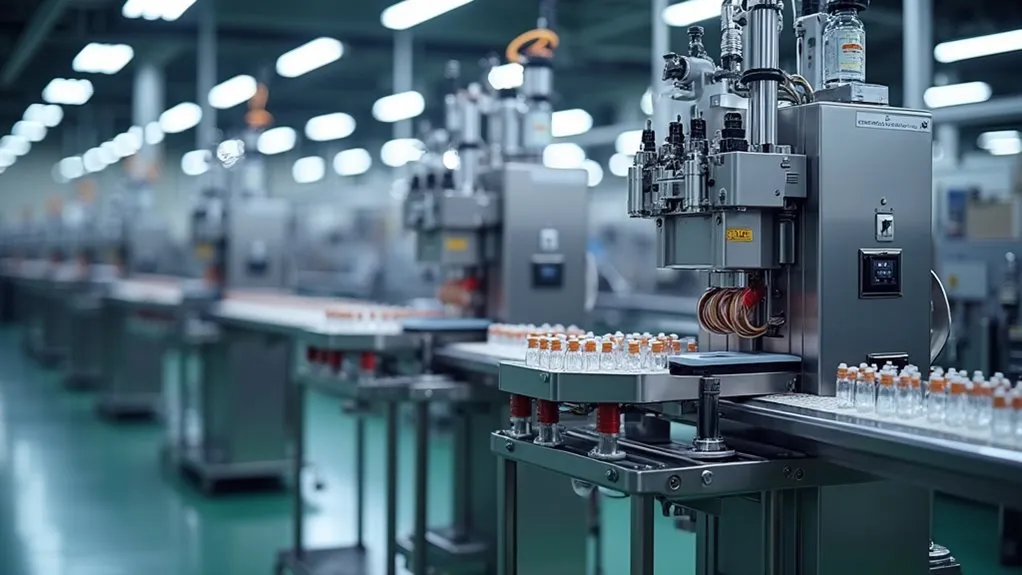

For efficient vial labeling in pharmaceutical production, three machines stand out. The Viallabeller Y-500 achieves 500 labels per minute with ±1mm precision, ideal for high-volume needs. HERMA’s High-Speed System labels up to 600 products per minute, ensuring GMP compliance with advanced sensors. Krones AG Modular Solution handles 100,000 containers hourly, offering scalable, flexible labeling techniques. Each system prioritizes accuracy and reliability. Exploring further will reveal deeper insights into their unique capabilities and benefits.

Key Takeaways

- Viallabeller Y-500 labels 500 vials per minute with ±1mm precision for high-volume pharmaceutical needs.

- HERMA High-Speed System achieves 600 labels per minute with GMP compliance and serialization.

- Krones AG Modular Solution labels up to 100,000 containers/hour with flexible, scalable stations.

- Y-500 ensures minimal downtime with durable, low-maintenance components for continuous operation.

- HERMA offers quick format changes and vision systems for efficient, compliant production.

Viallabeller Y-500: Precision and Speed for High-Volume Needs

How can pharmaceutical facilities meet the demands of high-volume production without compromising on accuracy? The Viallabeller Y-500 addresses this challenge with its capacity to operate at 500 labels per minute while maintaining a precision of ±1mm, adhering to stringent pharmaceutical standards. Its advanced automated sensors and feed systems ensure labeling consistency across vials of varying sizes, minimizing misalignment errors even at high speeds. This precision is critical for readable labeling under regulatory scrutiny, supporting both transparent and opaque containers with equal reliability.

Designed for continuous operation, the Y-500 optimizes production lines with minimal downtime, leveraging heavy-duty materials for durability in demanding environments. Its rugged components contribute to maintenance ease, requiring minimal intervention and maximizing uptime. Additionally, the Y-500 operates at a noise level below 75dB, ensuring a comfortable working environment for operators. By integrating thermal transfer printing for durable labels, the Viallabeller Y-500 delivers a solution that balances speed, accuracy, and reliability, meeting the rigorous needs of large-scale vial labeling in pharmaceutical facilities.

HERMA High-Speed System: Unmatched Accuracy in Pharma Labeling

The HERMA High-Speed System, featuring the HERMA 500 Label Applicator integrated into the 132M HC wrap-around labeler, sets a benchmark for precision and efficiency in pharmaceutical labeling. Engineered for speeds up to 600 products per minute, it excels in high-volume production of vaccine vials and healthcare items. Its continuously rotating starwheel and tool-free format changes ensure minimal downtime, enhancing operational throughput.

Designed for labeling scalability, the system adapts to diverse formats like glass vials and injection pens through modular architecture and adaptive positioning. Quality control is prioritized with compliance to GMP and 21 CFR Part 11 standards, supported by UV sensors, Cognex machine vision, and automatic rejection of defective items. Integrated serialization and cross-check validation further safeguard product integrity. With energy-efficient design and centralized control, the HERMA system seamlessly integrates into regulated environments, maintaining accuracy even on deep-frozen surfaces in cold storage applications.

Krones AG Modular Solution: Flexible and Scalable Production

Krones AG delivers a cutting-edge modular solution for vial labeling, engineered to meet the demands of flexible and scalable production. This system excels with speeds up to 100,000 containers/hour using reel-fed hotmelt labels, supporting diverse techniques like cold glue and self-adhesive applications. Its modular architecture, with exchangeable stations and hybrid setups, ensures adaptability without facility overhauls, while automation integration via Krones Contiroll and LabX software enables real-time monitoring and predictive maintenance.

| Feature | Specification |

|---|---|

| Max Speed (Hotmelt) | 100,000 containers/hour |

| Label Types Supported | Pre-cut, reel-fed, self-adhesive |

| Station Configurations | Seven types for tailored workflows |

| Energy Efficiency | Optimized motors for sustainability |

The compact footprint and spare parts consolidation enhance efficiency, aligning with environmental sustainability goals. With ergonomic designs and third-party device compatibility, Krones offers precise control and scalability for evolving production needs in vial labeling.

Tiếng Việt

Tiếng Việt 日本語

日本語 中文 (中国)

中文 (中国) 한국어

한국어