Alphapack labeling machines utilize advanced servo motors for precise label placement, offering high-speed synchronization with conveyor systems. Their robust stainless steel construction meets stringent hygiene standards, while integrated PLC and HMI provide intuitive control. These machines handle various labeling techniques and product types with efficiency. Advanced operational features, including IoT integration, enable rapid adaptation to production needs, promising deeper insights into their technological advancements.

Key Points to Remember

- Precision control with servo motors ensures accurate label placement within less than a millimeter.

- Advanced automation with PLC and touchscreen HMI for easy adjustments and real-time monitoring.

- Robust stainless steel construction meets hygiene standards, supporting durability and easy cleaning.

- Versatile labeling capabilities adapt to various product types, label sizes, and packaging shapes.

- Enhanced operational efficiency with high-speed automation and flexibility for different production scales.

Precision Control with Servo Motors

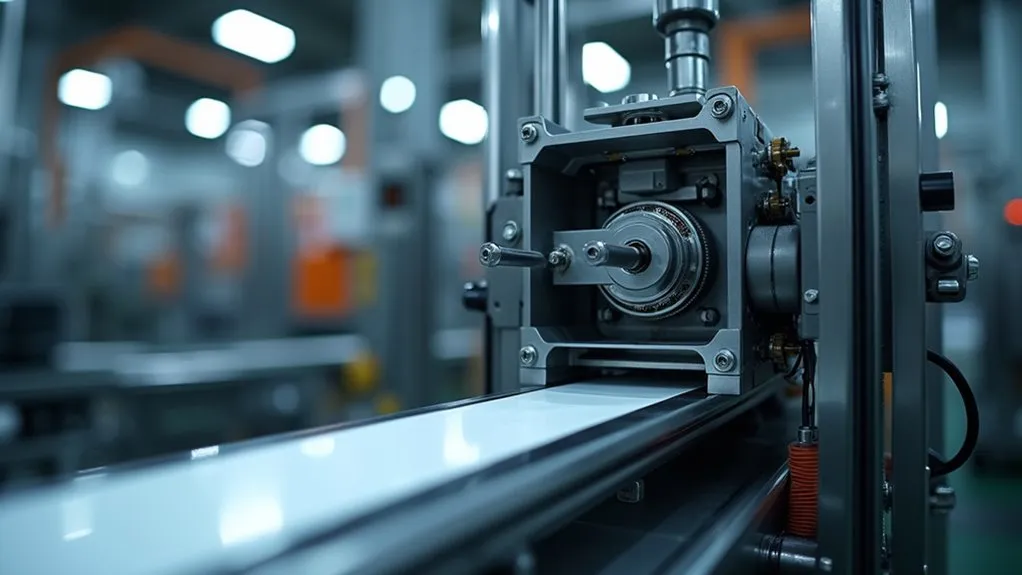

The precision of Alphapack labeling machines stems from the use of servo motors, delivering superior control and accuracy in the labeling process.

Servo motors enable high-speed synchronization with conveyor systems, ensuring labels are applied with precise timing and positional accuracy, even at fast production speeds. This synchronization is essential for maintaining efficiency without compromising label placement quality. Additionally, systems like the HERMA High-Speed System demonstrate the importance of advanced technology in achieving high-output production.

Moreover, servo motors provide unmatched positional accuracy, with label placement adjustments within less than a millimeter. This precision is due to the closed-loop feedback system inherent in servo motor technology, enabling real-time adjustments and virtually eliminating cumulative errors, thus ensuring each label meets exact standards. Furthermore, enhanced precision is maintained even at high speeds, ensuring seamless coordination with other automation systems like packaging machines, thereby guaranteeing accurate fill levels and label placement.

Advanced Automation and Control Systems

Alphapack labeling machines integrate advanced automation and control systems to enhance precision and efficiency. At the core of these systems is an integrated Programmable Logic Controller (PLC), which manages machine operations, paired with a touchscreen Human-Machine Interface (HMI) that provides an intuitive interface for easy parameter adjustments and configuration.

Real-time monitoring is enabled through advanced sensor integration, capable of accurately detecting products and ensuring precise label placement. Automation features extend to speed and adjustments, ensuring labeling quality is maintained through automatic synchronization with conveyor speeds and programmable label settings via a self-learning function. This comprehensive approach to automation and control underpins the machines’ reliability and performance in diverse packaging environments, similar to automation standards in 2025 labeling solutions.

Durable and Hygienic Construction

Utilizing high-quality stainless steel in their machine construction, Alphapack not only ensures compliance with stringent food industry hygiene standards but also provides a robust framework capable of withstanding the rigors of continuous industrial use.

The use of stainless steel, known for its corrosion resistance and non-porous surface, prevents bacterial growth and enhances machine durability. Designed with hygienic principles, Alphapack machines feature smooth, accessible surfaces for easy cleaning without residue buildup, minimizing crevices where product could accumulate.

Strict adherence to material and durable construction standards not only supports compliance with Good Manufacturing Practices (GMP) but also maximizes uptime and reliability of Alphapack machines in demanding production environments. Additionally, their machines are equipped with advanced IoT integration to improve performance and operational efficiency.

Versatile Labeling Capabilities

Offering a comprehensive range of labeling solutions, Alphapack machines excel in adapting to various product types, shapes, and sizes of packaging.

These machines are designed to handle multiple labeling techniques, including full wrap-around, front-and-back, and partial wrap-around, accommodating diverse packaging shapes such as round, square, and oval.

They are capable of labeling unstable products like non-standing round bottles and can be configured for both right- and left-handed operation.

With the ability to handle various label sizes and types, including self-adhesive and shrink labels, Alphapack machines ensure precise label application, suitable for industries like food and beverage, pharmaceuticals, and cosmetics. Moreover, their advanced technology features capabilities similar to those in high-speed labeling machines, enhancing efficiency and output in fast-paced production environments.

Improved Operational Efficiency

While the market demands fast and reliable packaging solutions, Alphapack labeling machines stand out by not only meeting but exceeding expectations through enhanced operational efficiency.

These machines provide high-speed automation with models like the Alpha HSM handling line speeds up to 500 feet per minute, ensuring rapid throughput. Servo-driven labeling heads synchronize with conveyor speeds, maintaining high-speed, high-quality labeling. This automation minimizes reliance on human labor, reducing costs and increasing efficiency.

The machines’ flexibility allows for easy setup and adjustments, accommodating various production scales. Production scalability is further supported by simple interfaces and remote configuration capabilities, enabling rapid adaptation to changing production demands.

Tiếng Việt

Tiếng Việt 日本語

日本語 中文 (中国)

中文 (中国) 한국어

한국어