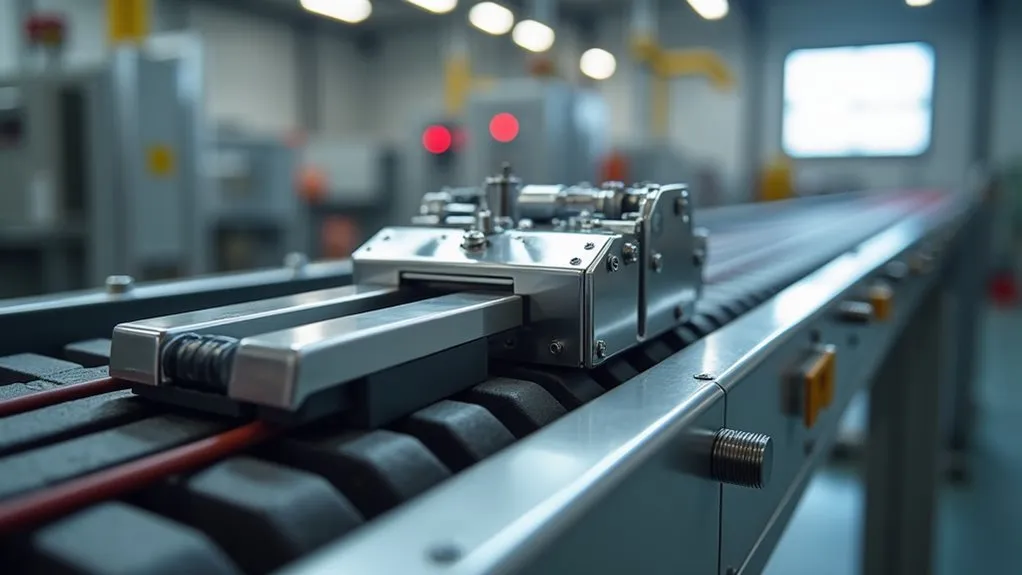

Siemens belt scales provide unmatched precision, innovative load cell design, robust construction, advanced integration, user-friendly installation, wide industrial applications, and comprehensive data functionality. Their accuracy, reliability, and adaptability make them essential for material handling. With features that enhance operational efficiency and decision-making, Siemens belt scales are integral to optimizing industrial processes. Exploring their advanced capabilities reveals how they set new standards in weighing technology.

Key Takeaways

- Siemens belt scales deliver high-precision measurements with accuracy up to ±0.25% or ±0.125%, achieved through advanced technology and periodic calibration.

- Innovative load cell design and robust construction ensure accurate and durable weight measurements with minimal maintenance requirements.

- The scales offer advanced integration into existing systems and user-friendly installation, with comprehensive communication protocols to simplify process control.

- Comprehensive diagnostics and data management enable rapid issue resolution, detailed trend analysis, and informed decision-making.

- The scales provide precise measurements and sophisticated control features, improving process management and efficiency in various material handling applications.

Unmatched Precision and Accuracy

Precision and accuracy form the foundation of Siemens belt scale systems, setting an industry standard few can match. With high-precision models ensuring accuracy of ±0.25% or even ±0.125%, these systems guarantee consistently reliable measurements.

Calibration methods, such as material tests and the use of static test weights, are essential to maintaining this level of accuracy. Siemens recommends periodic calibration to mitigate error factors like idler misalignment and improper belt tension, which can significantly impact measurement accuracy. Advanced technology is employed to ensure precise analysis and support diverse applications across various industries.

Innovative Parallelogram Load Cell Design

Siemens employs an innovative parallelogram load cell design in their belt scale systems, setting a benchmark in weighing technology. This design utilizes parallelogram mechanics to ensure that only vertical forces from the material weight on the conveyor are measured, effectively eliminating horizontal forces such as roller friction.

The unique load cell mechanism enables superior linearity and minimal hysteresis, resulting in highly accurate weight measurements. Particularly beneficial in applications with uneven or light product loads, these load cells provide rapid and precise responses to material load changes.

The robust construction and absence of moving parts facilitate easy installation and minimal maintenance, making them ideal for a wide range of load cell applications in demanding industrial environments.

Robust Construction for Enhanced Durability

Siemens belt scales are designed with robust construction to ensure durability in harsh environments, featuring heavy-duty frames and durable materials like stainless steel load cells and sturdy aluminum enclosures.

The scales’ design, including the absence of moving parts and protection against environmental factors like extreme temperatures and dust, minimizes maintenance requirements.

The combination of durability and low maintenance makes Siemens belt scales suitable for demanding industries including mining, quarrying, and chemical processing.

Durability in Harsh Environments

In the realm of demanding industries such as mining, aggregates, cement, and mineral processing, where conditions are often harsh and unforgiving, the durability of Siemens belt scales stands out.

Siemens belt scales are engineered with durable materials, such as stainless steel, to ensure corrosion resistance and environmental adaptability. For instance, the Milltronics MSI features 17-4 PH stainless steel load cells, highly resistant to moisture and corrosion.

These scales are designed to operate effectively across a wide temperature range, making them suitable for applications in both cold and tropical climates.

The integration of protective enclosures, such as the weatherproof rugged enclosure of the Milltronics BW500, further enhances the resilience of these belt scales in harsh conditions.

Minimal Maintenance Requirements

The minimal maintenance requirements of Siemens belt scales are a testament to their robust construction and field durability. Designed without moving parts, these scales reduce the need for frequent maintenance, with periodic calibration checks being the primary requirement. The modular design ensures easy assembly and rapid installation, often without requiring modifications to existing conveyor structures. Precision components, including stainless steel load cells in some models, enhance durability. Periodic checks for material buildup and simple push-button calibration maintain system integrity.

| Feature | Benefit |

|---|---|

| No moving parts | Reduced maintenance needs |

| Modular construction | Easy assembly and installation |

| Precision components | Reliable calibration over time |

| Stainless steel load cells | Enhanced durability |

| Push-button calibration | Simplified maintenance process |

Advanced Integration Capabilities

Advanced integration capabilities are a cornerstone of Siemens belt scales, providing users with seamless integration of these devices into existing control and data acquisition systems.

This seamless integration is achieved through:

- Direct module integration into the SIMATIC S7-1200 system

- Commissioning via the Totally Integrated Automation Portal (TIA)

- Use of pre-programmed function blocks for simplified integration

The scales support a wide range of comprehensive communication protocols, including PROFIBUS DP, ProfiNet, and Modbus TCP/IP, ensuring compatibility with various industrial networks.

These advanced integration capabilities enable better process control and data monitoring, making Siemens belt scales a versatile solution for industrial weighing applications.

User-Friendly Installation and Maintenance

Siemens belt scales feature user-friendly installation and maintenance, designed to minimize downtime and simplify operational processes.

The installation process benefits from a straightforward procedure involving minimal components, drop-in operation for models like the MSI, and guided procedures ensuring rapid setup.

Retrofitting into existing conveyor structures is made easy with the modular design of some models like the MBS.

Siemens’ MBS models feature a modular design, facilitating easy retrofitting into existing conveyor structures for seamless integration and enhanced operational efficiency.

Maintenance tips highlight the advantage of no moving parts in Siemens belt scales, limiting maintenance needs primarily to periodic calibration checks and debris removal around load cells.

These user-friendly aspects underscore Siemens’ commitment to delivering reliable and efficient weighing solutions, easily installed and maintained in various industrial environments.

Wide Range of Industrial Applications

Across a broad spectrum of industries, from the rugged terrain of mining and quarrying to the precise requirements of food and beverage production, Siemens belt scales excel in adaptability, precision, and durability.

These scales provide tailored solutions that meet the specific needs of various sectors, demonstrating a high degree of industry versatility.

- Diverse Applications: Siemens belt scales are critical in primary extraction industries for continuous conveyor weighing and integral in aggregates and cement for material management and product quality.

- Precision and Control: In the food and beverage sector, they ensure accurate measurements essential for product consistency, supporting light to medium applications with models like the Milltronics WD600 designed for slider bed conveyors. These scales excel in weight precision through advanced technology minimizing variances, crucial for regulatory compliance.

- Integration and Efficiency: These scales can be fully integrated into plant automation systems, supporting inventory management and process control, essential for operational efficiency across all industries.

Comprehensive Data and Control Functions

Beyond their versatility across industries, Siemens belt scales are equipped with comprehensive data and control functions that set them apart in the market.

These scales feature advanced microprocessor integrators, such as the Milltronics BW500, which not only process signals from load cells and speed sensors but also provide comprehensive diagnostics for rapid identification and resolution of operational issues.

The system’s data logging capabilities, supported by SITRANS RD500, enable in-depth trend analysis and record storage, essential for operational transparency and decision-making.

The combination of precise measurement, sophisticated control features, and extensive data management options makes Siemens belt scales indispensable tools for enhancing efficiency and productivity in material handling processes.

Tiếng Việt

Tiếng Việt 日本語

日本語 中文 (中国)

中文 (中国) 한국어

한국어