High-speed labeling machines, including Krones AG’s Contiroll, Sidel’s EvoDECO, Sasib’s SLM Flex, Weber’s Alpha HSM, Quadrel’s Q44, HERMA’s 500 applicator module, and Primera’s AP-Series, deliver precise and efficient solutions for canned food labeling. These machines ensure accurate label placement and adaptability to diverse can shapes and production scales. Exploring these technologies reveals their critical role in enhancing production efficiency and brand visibility in the competitive food industry.

Key Points

- Krones Contiroll and Ergomodul systems offer high-speed, precise can labeling with advanced automation for rapid changeovers.

- Sidel’s EvoDECO platform provides versatile, sustainable labeling solutions with high-speed capabilities and minimal adhesive use.

- Weber’s Alpha HSM offers customizable configurations for diverse labeling needs, operating at high speeds with zero downtime.

- Quadrel’s Q44 delivers high-volume, precise labeling, seamlessly integrating with Allen-Bradley PLC for user-friendly operation.

- Primera’s AP-Series provides semi-automatic labeling for cans, bottles, and jars, with efficient, wrinkle-free labeling up to 1,200 containers per hour.

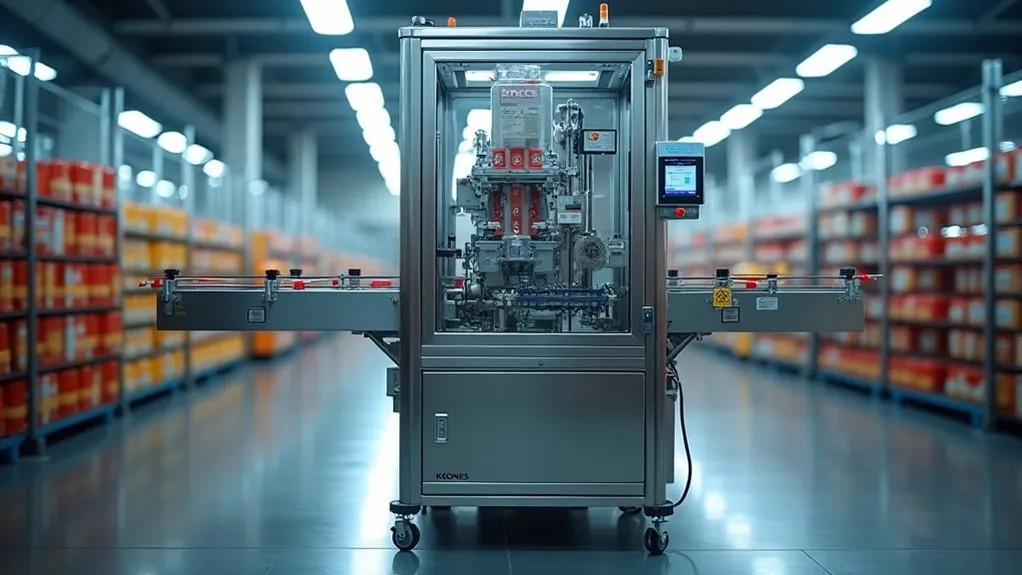

High-Speed and Precision with Krones AG Labelers

Krones AG offers a range of high-speed precision labeling machines designed to meet the demands of modern canning operations.

The Contiroll system, a benchmark for wrap-around labeling, achieves speeds of up to 800 pieces per minute using servo technology for precise label application.

The Ergomodul series features a modular design with automated coupling, enabling continuous high-speed labeling. High-speed user interface access via personal transponders enhances operational efficiency.

Krones machines ensure precise label placement through rotary container handling, servo-controlled applicators, and optional camera-based alignment.

With advanced automation, including the LineXpress program for rapid changeovers, Krones delivers efficient solutions for high-volume canning facilities requiring reliable, high-speed labeling performance.

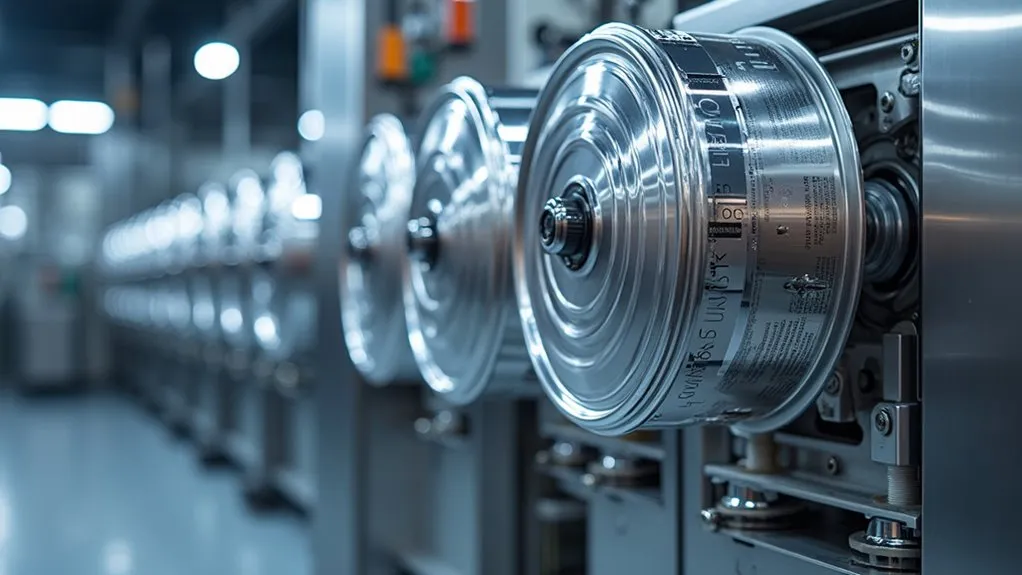

Sustainable Labeling Solutions from Sidel Group

Sidel Group, a global packaging solutions provider, offers the EvoDECO modular labeling platform, a model of versatility and sustainability in canned food labeling.

This platform supports up to four labeling technologies and accommodates various container types, shapes, and materials, delivering unmatched versatility.

With features like an advanced glue management system, Sidel ensures precise adhesive application, reducing consumption and waste.

The system’s high-speed capabilities, reaching up to 72,000 pieces per hour with a 98% efficiency rate, highlight its operational excellence.

Achieving operational excellence, Sidel’s EvoDECO labeling system handles up to 72,000 pieces per hour with an impressive 98% efficiency rate.

Furthermore, EvoDECO’s ability to handle ultra-thin labels and its focus on reducing container weight reflect Sidel’s commitment to sustainability and eco-friendly practices, making it a leader in environmentally conscious labeling solutions. Additionally, the integration of AI optimization in systems like EvoDECO enhances efficiency and predictive maintenance, ensuring scalability and consistent performance.

Versatile Can Labeling with Sasib SLM & SLM Flex

The Sasib SLM and SLM Flex labelers deliver high performance, achieving up to 160 pieces per minute with the SLM model. Precise can orientation is maintained through features like servo motors for real-time adjustments and the use of delta robots in the SLM Flex for product positioning. These machines also showcase design versatility with a modular architecture, enabling adaptation to various can shapes and integration into diverse production lines. Businesses can benefit from high-speed transport capabilities, enhancing overall operational efficiency and ensuring timely delivery of labeled products.

High-Speed Performance

With a focus on high performance, the Sasib SLM and SLM Flex offer versatile can labeling solutions, meeting the stringent demands of modern production lines.

These machines are designed for efficient and rapid label application, maintaining production efficiency through:

- High-Speed Operation: The Sasib SLM achieves production speeds of up to 160 pieces per minute, while the SLM Flex operates continuously to maximize labeling efficiency.

- Master-Slave Roll Change: The SLM employs a master-slave roll change solution, eliminating slowdowns during the process.

- Servo Motor Integration: Both models use servo motors for precise adjustments and real-time corrections, ensuring accurate label positioning without compromising speed.

These features ensure that the Sasib SLM and SLM Flex deliver high performance without sacrificing accuracy or quality, making them ideal for demanding production environments.

Orientation Precision

Can orientation precision is a critical aspect of the labeling process, which the Sasib SLM and SLM Flex address adeptly, complementing their high-speed capabilities.

Using advanced orientation technology, these machines ensure label accuracy through the use of delta robots and servo motors. The SLM Flex, in particular, employs three delta robots for precise product orientation, enabling real-time label position adjustments.

This system, combined with integrated vision systems and sensors, ensures consistent label alignment on each can. With the ability to handle various can shapes while maintaining high precision, the Sasib SLM and SLM Flex represent the pinnacle of labeling technology.

Design Versatility

The Sasib SLM and SLM Flex embody versatility in their design, offering comprehensive solutions for diverse can labeling needs.

Their adaptable design and modular efficiency are demonstrated through:

- Modular Architecture: Enables seamless integration and future modifications.

- Production Speed: Capable of labeling up to 160 cans per minute without slowdowns during roll changes.

- Handling Diverse Shapes: Specifically designed to accommodate both round and non-round cans with precise orientation mechanisms.

These features ensure that the machines can easily adapt to different can shapes and materials, delivering a highly efficient and adaptable labeling process.

Weber’s Alpha HSM for Zero-Downtime Labeling

The Alpha HSM labeler, a product of Weber’s innovation, stands out in the field of labeling technology with its modular design and high-speed capabilities.

Weber’s Alpha HSM redefines labeling with its modular design and unmatched speed, setting a new standard in labeling technology.

This machine is designed with modular drive units, label detection modules, dispensing units, winding units, and rewinders, allowing customizable configurations to meet diverse labeling needs.

Operating at speeds of up to 500 feet per minute and offering an optional parallel mode for zero downtime, the Alpha HSM ensures continuous operation.

Its IP65 rating and precise labeling within ±0.01 inches make it a durable and reliable choice for high-demand environments. Additionally, its high-speed labeling efficiency reflects the growing trend toward automation in labeling processes across industries.

Quadrel’s Q44 for High-Volume, High-Precision Labeling

The Quadrel Q44 labeling system is designed for high-volume, high-precision applications, offering a robust solution for demanding production environments.

This system excels in three key areas:

- High Performance: Capable of achieving speeds up to 150 products per minute, with configurations available for up to 300 ppm, ensuring efficient throughput.

- Label Placement Precision: Delivers superior accuracy up to ±1/32 inch, essential for minimizing waste and achieving a uniform appearance.

- Integration and Control: Incorporates Allen-Bradley PLC controls and a user-friendly color touchscreen interface, facilitating seamless integration into complex packaging lines and enhancing label customization.

Additionally, the Q44’s compatibility with various container shapes ensures versatility in dynamic production environments, making it ideal for both high-volume applications and diverse product lines.

The Q44’s automation benefits and robust construction make it an ideal choice for demanding production environments, delivering both efficiency and reliability.

HERMA’s Precision Engineering in Semi-Automatic Labelers

Shifting focus to HERMA’s precision engineering in semi-automatic labelers, these machines offer a blend of manual initiation and automated processes, embodying German craftsmanship renowned for precision and durability.

The HERMA 211 and 414 models represent this approach, integrating the high-performance HERMA 500 applicator for core functionality. Designed for operator flexibility, these labelers accommodate various product diameters and surfaces, from cylindrical items to flat and curved containers.

With labeling speeds of up to 40 units per minute, these machines enhance labeling efficiency while maintaining precision. Their modular design allows for future upgrades, while optional printing units and camera systems can be integrated for added functionality, ensuring these labelers meet diverse industrial requirements.

Primera AP-Series Technology for Efficient Cylindrical Labeling

Primera Technology’s AP-Series provides a semi-automatic labeling solution designed specifically for cylindrical containers, such as cans, bottles, and jars, making it an ideal choice for canned food products.

With labeling speeds of up to 5.3 inches per second, these machines can efficiently label up to 1,200 containers per hour, ensuring high productivity for food manufacturers.

The AP-Series features a spring-loaded pressure arm that ensures wrinkle-free label application, contributing to a professional finish for each product.

Key Features of the AP-Series

Efficient and versatile, Primera Technology’s AP-Series labelers are designed to simplify the labeling process for cylindrical containers.

These machines accommodate a wide range of label and container sizes, making them suitable for diverse applications.

Key features include:

- High-speed application, with the AP380 model offering a 30% speed increase over other models.

- Compatibility with container widths from 1 inch to 9.4 inches and diameters from 0.6 inch to 6.7 inches.

- Simple operation, including quick setup, easy operation, and an integrated spring-loaded pressure arm for wrinkle-free label application.

Ideal Application Scenarios

When businesses need a reliable and efficient solution for labeling cylindrical containers, Primera Technology’s AP-Series labelers offer unmatched versatility across various industries.

These machines are ideal for small to medium-sized businesses transitioning to semi-automatic labeling, enhancing labeling efficiency and supporting business scalability.

In the food and beverage industry, the AP-Series excels at labeling a wide range of products, from wine bottles to specialty food jars, ensuring a professional appearance.

The health, beauty, and cosmetics sectors benefit from wrinkle-free application on lotions and small-radius containers, while industrial and chemical applications rely on the AP-Series for robust and accurately placed labels.

With quick setup and easy operation, along with a compact design, the AP-Series is well-suited for operations requiring flexibility and efficiency.

Tiếng Việt

Tiếng Việt 日本語

日本語 中文 (中国)

中文 (中国) 한국어

한국어